Why Membrane Layer Changes Are Necessary for Resilient Control Equipment

Membrane switches play a pivotal role in ensuring the sturdiness and reliability of control systems across numerous industries. Their unique construction allows them to endure difficult environmental variables such as moisture, temperature extremes, and physical wear. This resilience not just expands the life-span of the systems they offer yet additionally lessens upkeep requirements. As we check out the multifaceted advantages of membrane buttons, it comes to be apparent that their relevance transcends mere performance, affecting individual experience and operational efficiency. What further ramifications do these attributes hold for the future of control system design?

Summary of Membrane Buttons

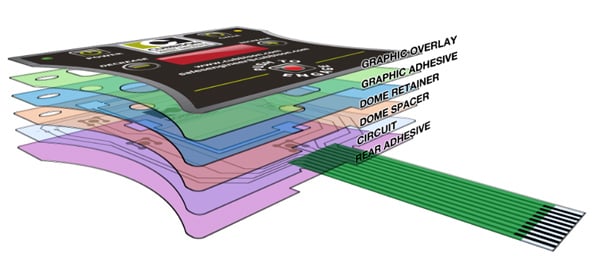

Membrane layer switches are versatile and dependable parts generally made use of in numerous electronic control systems. The visuals overlay supplies both functional and visual style, while the spacer layer makes sure that the switches are triggered just when pressed.

Membrane switches are commonly preferred in applications requiring a compact and lightweight layout, making them ideal for portable devices, clinical devices, and industrial machinery. They can be personalized to meet particular individual requirements and can integrate different features such as backlighting, responsive responses, and several colors. Additionally, membrane layer switches are immune to dirt, moisture, and contaminants, making them suitable for environments where durability is essential.

Benefits of Resilience

In lots of applications, the sturdiness of membrane layer changes offers significant advantages that boost their general performance and reliability. These switches are created to withstand rough atmospheres, making them optimal for use in requiring conditions such as high moisture, severe temperature levels, and exposure to chemicals. Their robust building aids to avoid damage from physical influence, ensuring resilient functionality and decreasing the demand for regular replacements.

Furthermore, membrane buttons are immune to deterioration, which is important in applications where constant communication occurs. This longevity converts to reduce upkeep prices, as organizations take advantage of decreased downtime and fewer service interruptions. The encapsulated design of membrane layer changes protects internal components from dust and wetness ingress, more contributing to their life expectancy (membrane switch).

Another benefit is their capability to keep constant efficiency in time. With a high resistance for mechanical tension, these buttons maintain their tactile comments and electrical integrity, guaranteeing user satisfaction. Inevitably, the toughness of membrane layer changes not just improves operational performance but likewise cultivates confidence in their reliability, making them a favored option for control systems across numerous sectors.

Applications in Various Industries

Long lasting control systems employing membrane layer buttons locate extensive applications across a series of markets, each gaining from the one-of-a-kind features these buttons provide. In the medical sector, membrane layer buttons are crucial for tools such as individual displays and diagnostic devices, where dependability and ease of cleansing are critical. Their resistance to dampness and pollutants guarantees they keep performance in clean and sterile environments.

The auto sector leverages membrane switches for dashboard controls and infomercial systems, where they provide sleek, low-profile interfaces that boost user experience. These buttons are likewise created to stand up to harsh problems, including direct exposure to severe temperature levels and resonances.

In commercial setups, membrane buttons are frequently made use of in equipment control panels, providing responsive feedback and resilience required for high-usage applications. Their ability to stand up to chemicals makes them ideal for producing settings where spills and pollutants are frequent.

Customer electronics, such as kitchen home appliances and remote controls, likewise utilize membrane switches for their flexibility and cost-effectiveness. Overall, the flexibility and robust nature of membrane layer switches over make them important across various markets, ensuring efficient operation here are the findings and longevity in control systems.

Design and Visual Appeal

While performance is paramount, the layout and aesthetic charm of control systems geared up with membrane layer switches play a vital duty in customer involvement and general experience (membrane switch). The aesthetic design of these switches can substantially affect customer perception and interaction. A well-designed membrane layer button boosts the attractiveness of the tool, making it a lot more enticing to individuals and cultivating a connection between the customer and the item

Membrane layer changes offer a terrific offer of flexibility in layout, permitting makers to personalize graphics, shades, and structures to straighten with brand name identification and product aesthetic appeals. Making use of lively shades and unique patterns can draw attention, while tactile comments can strengthen the user's communication with the tool. In addition, the capability to incorporate LED indicators and backlighting right into the membrane switch style gives both useful and visual advantages, improving exposure and usability in various environments.

Enhancing Customer Experience

In addition, membrane layer buttons can be tailored to integrate visual user interfaces, boosting usability by offering information in a clear see this site and instinctive manner (membrane switch). This customization can consist of icons, tags, and color coding that guide users through complicated capabilities effortlessly. Furthermore, their adaptability enables integration in numerous settings, guaranteeing regular efficiency whether in commercial equipment or consumer electronic devices

The durability of membrane switches also plays a critical duty in customer experience. By enduring rough conditions and extended usage, these buttons reduce the chance of system failings, thus promoting dependability and individual confidence. Inevitably, the tactical use membrane changes not just boosts functionality yet likewise considerably enriches user interaction with control systems, making them a vital element in modern design.

Final Thought